· timing belts · 14 min read

Complete Guide to GT2 Closed Loop Belts: Best Options and Uses

Discover the best GT2 closed loop belts for enhanced 3D printing performance. Our guide provides detailed insights, top product reviews, and expert tips to help you make informed choices.

In the realm of 3D printing, precision and efficiency are paramount. GT2 closed loop belts play a pivotal role in ensuring these qualities, delivering exceptional motion control and power transmission capabilities. In this comprehensive guide, we delve into the world of GT2 closed loop belts, exploring their key features, benefits, and applications. We present the top products in the market, empowering you to make informed decisions for your 3D printing endeavors. Whether you're a seasoned professional or a novice enthusiast, this guide will equip you with the knowledge and insights to optimize your 3D printing experience with GT2 closed loop belts.

Overview

PROS

- Accurate timing and precise motion control

- Durable rubber construction for extended lifespan

CONS

- May exhibit slight dimensional variations

- Limited stock availability

PAGOW's GT2 Closed Loop Timing Belts offer an exceptional solution for precise motion control in demanding 3D printing applications. With eight belts ranging from 110mm to 400mm in length, these belts ensure smooth and accurate movement of your printer's components. Constructed from high-quality rubber, these belts exhibit excellent wear resistance and durability, guaranteeing long-lasting performance. Whether you're a seasoned maker or just starting your 3D printing journey, PAGOW's timing belts will empower you to achieve optimal print quality and precision.

Incorporating these timing belts into your 3D printer setup is a breeze. Their closed-loop design eliminates the need for complex tensioning mechanisms, making installation and operation effortless. Moreover, the belts' precise tooth profile ensures positive engagement with your printer's pulleys, minimizing backlash and maintaining consistent motion. This translates into sharper prints, reduced layer shifting, and enhanced overall printing accuracy.

PROS

- Closed loop design ensures perfect alignment and consistent motion

- Constructed from durable rubber for exceptional longevity and reliability

- Compatible with 3D printers that utilize 6mm wide belts

- Provides precise and stable movement for optimal printing results

- 10-pack offers ample supply for multiple printer projects

CONS

- May not be suitable for applications requiring extreme precision

- Belt tension may require adjustment for optimal performance

The GT2 Closed Loop Belt is a high-quality timing belt designed specifically for 3D printers. Constructed from durable rubber, this belt offers exceptional strength and resilience, ensuring longevity and reliable performance. Its closed loop design guarantees perfect alignment and consistent motion, essential for achieving precise printing. The 6mm width ensures compatibility with a wide range of 3D printers, and with 10 belts included in the pack, you'll have a sufficient supply for multiple projects.

The GT2 timing belt is an upgrade from traditional belts, providing enhanced stability and accuracy. Its precision engineering minimizes backlash and ensures smooth, consistent motion throughout the printing process. This results in improved print quality and reduced printing errors. The durable construction withstands repeated use and maintains its integrity over time, making it an excellent choice for demanding printing applications.

PROS

- Exceptional precision ensuring accurate layer alignment

- Durable construction for extended usage and reduced maintenance

CONS

- May require some adjustment for optimal tensioning

The LC LICTOP GT2 Closed Loop Timing Belt is a high-precision component designed to enhance the performance of 3D printers. Constructed from premium rubber, this belt boasts exceptional durability, reducing the need for frequent replacements. Its closed-loop design ensures consistent tension throughout the printing process, guaranteeing accurate layer alignment.

The precision of the GT2 profile ensures smooth and precise movement of the printer's components, minimizing layer shifting and improving overall print quality. Whether you're a seasoned 3D printing enthusiast or just starting out, the LC LICTOP GT2 Closed Loop Timing Belt is an excellent choice for achieving professional-grade results. Its reliability and durability make it a worthwhile investment for any 3D printing setup.

PROS

- Precise and synchronous motion transmission for demanding applications

- Closed-loop design eliminates backlash and ensures accurate positioning

- Durable construction withstands high speeds and demanding loads

- Set includes multiple belt lengths and matching pulleys for versatile use

- Ideal for 3D printers, dishwashers, and packaging machinery

CONS

- May require tensioning adjustments for optimal performance

- Can be more expensive than open-ended belts

Experience unparalleled precision and reliability with our GT2 Closed Loop Timing Belt System. This exceptional set comprises 6 durable GT2 timing belts in various lengths (110mm, 158mm, 200mm, 300mm, 400mm, and 610mm) and 2 matching GT2 timing belt pulleys with 20 teeth and a 5mm bore. Each belt is meticulously crafted to ensure smooth and synchronous motion transmission, eliminating backlash and guaranteeing accurate positioning. The closed-loop design further enhances precision by maintaining constant tension throughout the system.

Constructed from high-quality materials, these belts are built to withstand high speeds and demanding loads, making them ideal for a wide range of applications. The set's versatility is further enhanced by the inclusion of various belt lengths, enabling you to tailor the system to your specific needs. Whether you're operating 3D printers, dishwashers, or packaging machinery, this timing belt system will empower your machines with exceptional precision and reliability. Embrace the new standard of motion control and elevate your projects to new heights with our GT2 Closed Loop Timing Belt System: the epitome of precision and durability.

PROS

- Durable nylon tooth surface for excellent grip and non-slip performance

- Optimized tooth profile for reduced backlash and improved accuracy

- Closed-loop design ensures stable and consistent tension

CONS

- May require proper tensioning to avoid skipping

- Not suitable for high-torque applications

The 10 x 200mm GT2 Closed Loop Timing Belt is an essential component for precise power transmission in 3D printing and CNC applications. Its nylon tooth surface provides superior grip, preventing slippage even under demanding conditions. The optimized tooth profile minimizes backlash, ensuring accuracy and repeatability in your projects.

The closed-loop design of this belt ensures consistent tension throughout its length, eliminating the risk of stretching or sagging. This translates to improved stability and reliability in your power transmission system. Whether you're building a new 3D printer, upgrading an existing CNC machine, or simply replacing a worn belt, this GT2 Closed Loop Timing Belt is an excellent choice for precision power transmission.

PROS

- Enhanced accuracy and precision for smoother belt-driven operations

- Closed loop design eliminates backlash and ensures consistent tension

- Non-slip surface provides reliable power transmission and reduced slippage

- Durable construction withstands demanding printing environments

- Suitable for various 3D printers and belt-driven applications

CONS

- May require precise pulley alignment for optimal performance

- Not compatible with all 3D printers without modifications

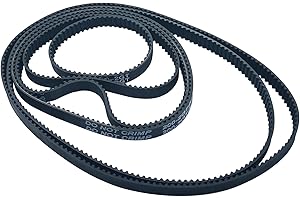

MOTOU's 10 x 2000mm GT2 Closed Loop Timing Belt offers a remarkable upgrade to your 3D printing setup. Its closed loop design effectively eliminates backlash, providing unparalleled accuracy and precision during belt-driven operations. The non-slip surface ensures reliable power transmission, reducing slippage and enhancing overall print quality.

Constructed from durable materials, this GT2 belt can withstand the rigors of demanding printing environments. Its compatibility with various 3D printers and belt-driven applications makes it a versatile solution for enhancing your printing capabilities. Whether you're looking to improve the precision of your prints or simply upgrade your printer's performance, the MOTOU Closed Loop Timing Belt is an exceptional choice.

PROS

- Exceptional closed-loop design for consistent tension and accuracy

- Durable rubber construction ensures longevity and resilience

- 500 evenly spaced teeth precisely engage with pulleys for smooth operation

- Optimized for 3D printers, providing reliable and precise motion control

CONS

- May require specific pulleys for optimal performance

- Not suitable for high-torque applications

Elevate your motorized applications with the unparalleled precision of our 2GT Closed Loop Belt. Expertly crafted from durable rubber, this belt boasts exceptional longevity and resilience, ensuring your projects run smoothly for years to come. The meticulously designed closed-loop construction maintains consistent tension throughout the belt's operation, eliminating slippage and ensuring unwavering accuracy.

With 500 precisely spaced teeth, this belt seamlessly engages with compatible pulleys, translating into smooth and precise motion control. Its optimized design makes it an ideal choice for 3D printers, where precision and reliability are paramount. Whether you're a seasoned professional or a hobbyist, the 2GT Closed Loop Belt empowers you to achieve flawless motion in your projects, unlocking a new level of precision and efficiency.

PROS

- Experience exceptional precision and accuracy in your 3D printing endeavors with our GT2 timing belt.

- Benefit from the enhanced belt tension and stability provided by the closed loop design, resulting in superior print quality.

- Enjoy hassle-free installation and maintenance thanks to the convenient pre-cut loop lengths.

- Choose from a range of perimeter options (110mm, 158mm, 200mm, 200mm, 280mm, 300mm) to suit your specific printer requirements.

CONS

- May require some adjustment to ensure optimal belt tension.

- Not suitable for use with high-torque applications.

Elevate your 3D printing experience with our GT2 Closed Loop Belt, meticulously crafted to deliver unmatched precision and reliability. Its closed loop design ensures exceptional belt tension and stability throughout the printing process, resulting in significantly improved print quality. Combined with its pre-cut loop lengths, installing and maintaining this timing belt is a breeze.

Our GT2 Closed Loop Belt is available in a range of perimeter options, empowering you to choose the perfect fit for your specific printer requirements. Whether you're a seasoned pro or just starting your 3D printing journey, this timing belt will empower you to achieve remarkable results with every print. Invest in precision, invest in our GT2 Closed Loop Belt today!

PROS

- High-quality rubber construction ensures durability and flexibility.

- 2GT 6mm pitch provides accurate and smooth motion transmission.

- Closed loop design eliminates the need for tensioning devices, reducing maintenance.

- Suitable for a wide range of 3D printers and other applications requiring precise timing.

CONS

- May require specialized tools for installation.

- Could be susceptible to wear and tear over extended periods of use.

The LC LICTOP GT2 Closed Loop Timing Belt is an essential component for any 3D printer or application where precise timing and motion control are crucial. Constructed from high-quality rubber, this belt offers exceptional durability and flexibility, ensuring smooth and reliable operation over extended periods. Its 2GT 6mm pitch provides accurate motion transmission, making it ideal for applications requiring precise positioning. The closed loop design eliminates the need for tensioning devices, simplifying installation and reducing maintenance requirements.

This timing belt is suitable for a wide range of 3D printers, including popular models from Creality, Ender, and Prusa. It can also be used in other applications such as CNC machines, robotics, and automation systems. Its versatility makes it a valuable addition to any maker's toolbox. However, it's important to note that installation may require specialized tools, and extended use could lead to wear and tear. Overall, the LC LICTOP GT2 Closed Loop Timing Belt is a high-quality and reliable solution for precise timing applications.

PROS

- Excellent dimensional accuracy for precise printing

- Closed-loop design ensures consistent tension and motion

CONS

- May require specific pulleys for compatibility

- Can be more expensive than open-loop belts

The 8PCS 2GT Closed Loop Rubber Belt offers a premium solution for 3D printing applications. Its closed-loop design ensures consistent tension and motion, leading to improved print quality and precision. The high dimensional accuracy of these belts ensures that your prints are dimensionally accurate, reducing the risk of errors and ensuring reliable results.

These belts are available in a range of lengths (110mm, 112mm, 122mm, 158mm, 200mm, 280mm, 300mm, 400mm) and a width of 6mm, providing versatility for different printer configurations. While closed-loop belts may be more expensive than open-loop belts, their enhanced performance and durability make them a worthwhile investment for demanding printing applications.

GT2 closed loop belts are indispensable components in 3D printing, offering a combination of precision, durability, and reliability. Our guide provides a comprehensive overview of these belts, covering various aspects such as their construction, materials, and performance characteristics. We also explore the top products in the market, offering detailed reviews to help you select the best GT2 closed loop belts for your specific needs. Additionally, we furnish you with expert tips and insights to ensure optimal belt performance and longevity. By leveraging this guide, you can unlock the full potential of GT2 closed loop belts, transforming your 3D printing experience and achieving remarkable results.

Frequently Asked Questions

What are the primary advantages of using GT2 closed loop belts in 3D printing?

GT2 closed loop belts excel in 3D printing due to their exceptional precision, durability, and reliability. They provide accurate motion control, ensuring smooth and consistent movement of print heads and other mechanical components. Additionally, their closed loop design eliminates backlash and slippage, resulting in enhanced print quality and reduced downtime.

Which factors should be considered when selecting a GT2 closed loop belt?

When choosing a GT2 closed loop belt, consider factors such as belt width, pitch, length, and material composition. The belt width determines the load-bearing capacity, while the pitch influences the accuracy of motion control. The length should correspond to the specific application and printer requirements. Additionally, the material composition impacts durability, flexibility, and resistance to wear and tear.

How can GT2 closed loop belts improve the overall performance of 3D printers?

GT2 closed loop belts contribute to enhanced 3D printing performance by providing precise motion control, reducing vibration and noise, and minimizing backlash. They facilitate smooth and accurate movement of print heads, leading to improved print quality and reduced printing time. Moreover, their durability and reliability minimize the risk of breakdowns and interruptions, ensuring a consistent and efficient printing process.

What are some tips for maintaining and extending the lifespan of GT2 closed loop belts?

To maintain and extend the lifespan of GT2 closed loop belts, regular cleaning and inspection are crucial. Remove any debris or contaminants that may accumulate on the belt surface. Additionally, proper tensioning is essential to prevent excessive wear and tear. Avoid over-tightening, as it can strain the belt and shorten its lifespan. Store belts in a cool, dry place when not in use to preserve their integrity and flexibility.

Are there any potential drawbacks associated with using GT2 closed loop belts in 3D printing?

While GT2 closed loop belts offer numerous advantages, there are a few potential drawbacks to consider. They may be more expensive than other types of belts, and their closed loop design limits their flexibility and adaptability to different applications. Additionally, they require precise installation and tensioning to ensure optimal performance, which may require some technical expertise.