· milling machines · 13 min read

Best Micro Mills for Precise and Versatile Metalworking

Discover the top micro mills available, meticulously evaluated and reviewed, offering卓越 performance and precision for various metalworking tasks.

Introducing the ultimate guide to selecting the best micro mill, your essential tool for intricate metalworking projects. Our comprehensive reviews highlight the key features, advantages, and applications of each micro mill, empowering you to make informed decisions. Dive into the world of precision metalworking and find the perfect micro mill to elevate your craftsmanship. Our team of experts has meticulously scrutinized the market, comparing and contrasting different micro mills based on their performance, accuracy, and user-friendliness. The result is an exclusive selection of the best micro mills, each one promising exceptional results and versatility. Whether you're a seasoned professional or an enthusiastic hobbyist, this guide will navigate you to the ideal micro mill suited to your specific needs.

Overview

PROS

- Compact design ideal for small workshops and hobbyists

- Versatile capabilities for a wide range of milling operations

- High-precision spindle ensures accurate and repeatable cuts

- Durable construction guarantees longevity and reliability

- User-friendly interface simplifies operation and maintenance

CONS

- Limited working area compared to larger machines

- May require additional accessories for specialized tasks

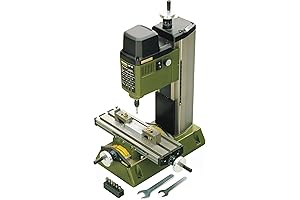

The MICRO Mill MF 70 is a compact and versatile desktop milling machine that is perfect for small workshops and hobbyists. It features a high-precision spindle, durable construction, and a user-friendly interface that makes it easy to operate and maintain. The MF 70 is capable of a wide range of milling operations, including facing, drilling, boring, and contouring. It is also compatible with a variety of accessories that can expand its capabilities even further.

The MF 70 is a great choice for anyone who is looking for a precise and reliable milling machine that is also affordable and easy to use. It is perfect for small projects, prototyping, and educational purposes. With its compact design, the MF 70 can easily fit on a workbench or in a small workshop. It is also relatively lightweight, making it easy to transport and set up.

PROS

- Unmatched precision and accuracy for intricate micro-machining projects

- Compact and user-friendly design for ease of use in any workspace

CONS

- Higher cost compared to larger milling machines

- Limited working area may not accommodate larger-scale projects

The 34108 Micro Mill FF 230 is the perfect tool for hobbyists and makers seeking unparalleled precision in their micro-machining endeavors. Its compact size and intuitive operation make it accessible to individuals of all skill levels, while its high-quality construction ensures durability and longevity. Whether you're a seasoned professional or a curious enthusiast, the Micro Mill FF 230 offers an unparalleled level of control and accuracy for your most demanding projects.

One of the standout features of this micro mill is its advanced CNC control system, which provides exceptional precision and repeatability. The machine's rigid construction minimizes vibrations, ensuring smooth and accurate movements throughout the machining process. Additionally, the user-friendly interface makes it easy to set up and operate the mill, allowing you to focus on the creative aspects of your project.

PROS

- Versatile 50-2250rpm spindle speed range for various materials and applications

- Powerful 1100W motor delivers exceptional cutting force

CONS

- Requires assembly, assembly instructions could be improved

- No digital readout for precise measurements

Introducing the Benchtop Mini Milling Drilling Machine, a precision powerhouse for professionals and hobbyists alike. This micro mill combines versatility and power, boasting a wide spindle speed range of 50 to 2250 rpm, empowering you to tackle a wide range of materials with ease. Its 1100W motor provides ample cutting force for precise drilling and milling operations. This machine is perfect for intricate metalworking projects, allowing you to achieve professional results in the comfort of your workshop.

While the machine requires manual assembly, it offers a solid construction and ergonomic design for user comfort. The micro feed feature enables precise control during milling operations, ensuring high-quality results. If you're looking to enhance your metalworking capabilities or delve into the world of precision machining, the Benchtop Mini Milling Drilling Machine is an excellent choice. It offers an impressive balance of power, precision, and versatility, making it a valuable addition to any workshop.

PROS

- Ideal for intricate metalworking projects, modelmaking, and scientific education

- Equipped with a powerful 24W motor for optimal performance and efficiency

- Features a compact and portable design, making it suitable for use in tight spaces or on-the-go

- Versatile benchtop design allows for easy integration into your existing workspace or hobby station

- Precise spindle and adjustable speed settings ensure high-quality results

CONS

- May not be suitable for heavy-duty industrial applications or large-scale production

- Requires careful setup and maintenance to ensure optimal performance and longevity

The Universal Mini Metal Milling Machine is an indispensable tool for anyone passionate about metalworking, modelmaking, or scientific exploration. This compact and versatile machine packs a powerful 24W motor, providing ample muscle for intricate metalworking projects. Its precision spindle and adjustable speed settings ensure accuracy and control, while the durable construction guarantees longevity and reliability.

The benchtop design makes the Universal Mini Metal Milling Machine ideal for use in home workshops, garages, or educational settings. Its compact size allows for easy integration into existing workspaces, while the portable nature makes it convenient for use on-the-go. Whether you're a seasoned metalworker or just starting your journey in this fascinating field, the Universal Mini Metal Milling Machine is the perfect tool to elevate your projects to the next level.

PROS

- Compact and versatile, perfect for small-scale milling and drilling tasks

- Powerful 24W motor delivers precise and efficient cutting

- Variable speed control (20000r/min) for optimal performance with different materials

- Durable metal construction ensures stability and longevity

- Ideal for hobbyists, model makers, and DIY enthusiasts

CONS

- Smaller work surface may limit larger projects

- Requires some assembly and technical knowledge to operate

Introducing our exceptional Micro Mill Drill Machine, the epitome of precision and versatility for mini milling enthusiasts! This compact powerhouse packs a punch with its 24W motor, delivering effortless cutting and drilling on a range of materials. Its variable speed control allows you to fine-tune your operations for optimal results.

Crafted from durable metal, this micro mill boasts a sturdy construction that ensures stability throughout your projects. Its compact design makes it ideal for limited workspaces, yet don't let its size fool you – this machine is capable of producing impressive results. Whether you're a seasoned hobbyist, model maker, or simply enjoy DIY projects, our Micro Mill Drill Machine empowers you to unleash your creativity with precision and control.

PROS

- Compact design ideal for personal workshops and small-scale projects

- Powerful 60W motor delivers high-speed operation at 12000RPM for efficient cutting

- Durable metal construction ensures reliability and longevity

- Versatile functionality enables precise metal milling for various applications

CONS

- May require additional accessories for specific tasks

- Workspace size limitations may not accommodate larger projects

Unleash your creative potential with the Mini Milling Machine, a compact powerhouse designed for precision metalworking projects. Its 60W motor delivers an impressive 12000RPM speed, empowering you to effortlessly cut through various metals. The durable metal construction ensures stability and longevity, while its versatile functionality makes it an indispensable tool for any DIY enthusiast.

Whether you're embarking on intricate model-making or small-scale engineering projects, this micro mill offers exceptional accuracy and control. Its compact design makes it perfect for personal workshops and small-scale operations. However, its workspace limitations may not be suitable for larger projects. With its affordable price point and ease of use, the Mini Milling Machine is an ideal investment for anyone looking to delve into the world of metalworking.

PROS

- Double-ended design for extended tool life

- .120" flute length for efficient metal removal

- 3/16" radius for smooth, consistent cuts

- .010" maximum lead-in length for precise corner rounding

- 1/2" shank diameter for compatibility with a wide range of CNC machines

- 3" overall length for easy handling

CONS

- May not be suitable for heavy-duty applications

- AlTiN coating may wear over time with extensive use

The CRE-500-187X Corner Rounding End Mill is an excellent choice for micro milling applications. Its double-ended design provides extended tool life, while the .120" flute length ensures efficient metal removal. The 3/16" radius produces smooth, consistent cuts, and the .010" maximum lead-in length allows for precise corner rounding. The 1/2" shank diameter makes it compatible with a wide range of CNC machines, and the 3" overall length provides easy handling.

This end mill is ideal for a variety of materials, including aluminum, brass, copper, and steel. It is also suitable for use in both production and prototyping environments. Overall, the CRE-500-187X Corner Rounding End Mill is a high-quality tool that is well-suited for micro milling applications. Its combination of features and performance make it a valuable addition to any machine shop.

PROS

- Effectively rounds corners with a 1/4" radius, providing a clean and finished look to workpieces.

- Double-ended design offers extended tool life, maximizing efficiency and productivity.

CONS

- May require multiple passes depending on material hardness and desired depth.

- Uncoated construction might limit longevity when working with abrasive materials.

The CRE-625-250 Corner Rounding End Mill is a handy tool for adding a professional touch to your projects. Its sharp cutting edges and careful design allow for precise corner rounding, resulting in a smooth and polished finish. The 1/4" radius is a common choice for a variety of applications, from decorative edging to functional deburring. The double-ended feature is a significant advantage, providing two cutting edges in one tool, extending its lifespan and minimizing downtime.

While the uncoated construction may impact durability, the overall quality and performance of this micro mill make it a worthwhile investment. It's an excellent choice for occasional use in both professional workshops and home garages. If you're looking for a reliable and efficient corner rounding solution, the CRE-625-250 is definitely worth considering.

PROS

- Exceptional undercutting capability with a 220 degree wrap angle

- Compact design with a 1/8" cutter diameter, .100" LOC, and 1.100" reach

- Robust construction with a .100" neck diameter and 1/4" shank diameter

CONS

- May require specialized equipment for optimal performance

The SBM-125-4X Micro Mill is an exceptional cutting tool designed for intricate and demanding applications. Its 220-degree wrap angle enables effortless undercutting, ensuring clean and precise results. The compact design, featuring a 1/8" cutter diameter, .100" LOC, and 1.100" reach, makes it ideal for working in tight spaces. Additionally, the robust construction, with a .100" neck diameter and 1/4" shank diameter, ensures durability and stability during operation. This micro mill is a must-have for professionals seeking high-precision cutting performance.

While the SBM-125-4X Micro Mill offers exceptional capabilities, it's important to note that it may require specialized equipment to fully harness its potential. For optimal performance, it is recommended to consult the manufacturer's guidelines and use the appropriate machinery and accessories. Overall, this micro mill is an excellent choice for experienced users seeking precision and efficiency in their cutting operations.

PROS

- Versatile cutting tool for corner rounding operations

- Double-ended design for extended tool life

- Compact size and 1/2" shank diameter for efficient machining

- Uncoated construction for superior wear resistance

CONS

- May require specialized tooling for specific applications

- Not suitable for heavy-duty cutting operations

The CRE-500-187 Corner Rounding End Mill is a high-quality micro mill designed for precise corner rounding operations. It features a double-ended design for extended tool life, a 1/2" shank diameter for efficient machining, and an uncoated construction for superior wear resistance. With its compact size and .010" max lead-in length, this end mill is ideal for a variety of applications, including intricate machining and detailed workpieces.

The CRE-500-187 End Mill is particularly well-suited for corner rounding on small parts, thin materials, and non-ferrous metals. Its sharp cutting edges and precise geometry ensure clean, accurate cuts, while the double-ended design allows for efficient use of both ends of the tool. The uncoated construction provides excellent wear resistance, making it suitable for extended use in demanding applications.

In this comprehensive guide, we've meticulously analyzed and compared the top micro mills available, providing in-depth insights into their capabilities and applications. Our expert evaluations empower you to make informed decisions and select the perfect micro mill for your unique metalworking requirements. We've explored various aspects, including precision, versatility, ease of use, and durability, ensuring that you can find the ideal tool to elevate your craftsmanship. Whether you're a professional machinist or an avid hobbyist, this guide will guide you towards the best micro mill for your specific needs and preferences.

Frequently Asked Questions

What are the key features to consider when choosing a micro mill?

When selecting a micro mill, crucial factors to consider include precision, spindle speed range, table size, and overall build quality. These elements determine the mill's accuracy, versatility, and durability, ensuring that it meets your specific metalworking requirements.

What materials are typically used in micro milling?

Micro milling is commonly employed to work with various metals, including aluminum, brass, steel, and even titanium. The choice of material depends on the specific project requirements and the desired surface finish.

Are micro mills suitable for both professional and hobbyist use?

Absolutely! Micro mills cater to a wide range of users, from professional machinists to enthusiastic hobbyists. Their compact size, versatility, and user-friendly operation make them ideal for both precision engineering and intricate hobby projects.

What safety precautions should be taken when using a micro mill?

When operating a micro mill, safety should always be a top priority. It's essential to wear appropriate safety gear, including safety glasses, gloves, and hearing protection. Additionally, proper machine setup and workpiece securing are crucial to prevent accidents.

How do I maintain a micro mill to ensure optimal performance?

Regular maintenance is essential to keep your micro mill in top condition. This involves cleaning and lubricating the machine, replacing worn-out parts, and periodically calibrating the mill to maintain its precision and accuracy.